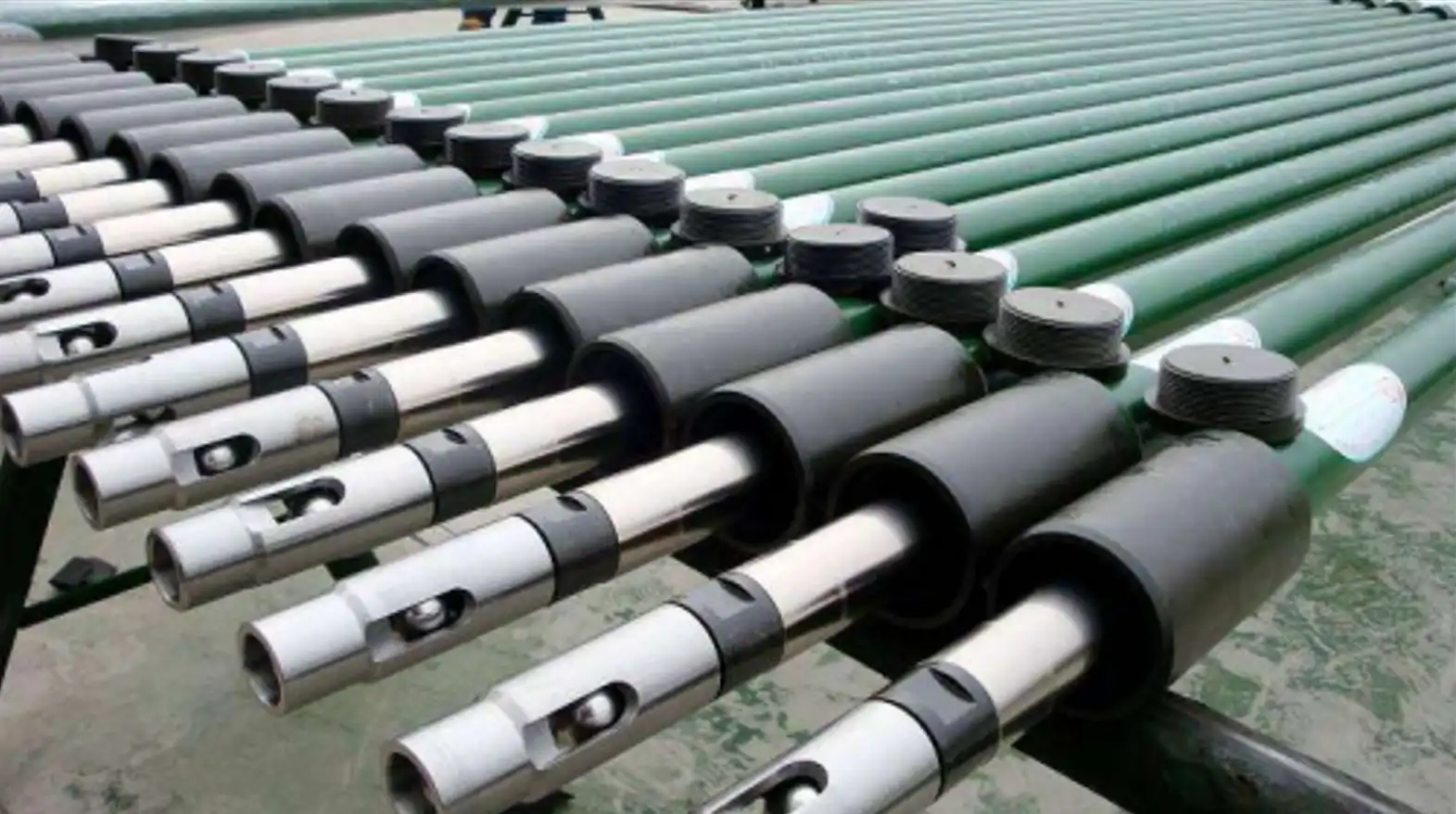

Overview:

No need to lift the oil tubing during pump inspection, shortening operation time and reducing the number of tubing unscrews, thus extending tubing life and lowering operational costs.

Simply lifting the rod string can connect the oil and casing, enabling forward well flushing, downhole testing, and thermal recovery operations such as steam injection, all without lifting the tubing string, providing convenience and reliability.

The sucker rod pump is partly protected by an outer pipe, suitable for layered production wells with packers, preventing pressure deformation of the pump barrel and subsequent pump sticking.

No need for an oil release device—after unsealing by lifting the rod string, self-draining is enabled instantly, which is cost-saving, reliable, and safe.

Technical Parameters Table:

| Standard | Model | Nominal Diameter (mm) | Plunger Length (m) | Stroke (m) | Pumping Rate (m³/d) | Tubing Thread | Rod Thread |

|---|---|---|---|---|---|---|---|

| GB/T186 07 | 20(25)-125 RHAM | 32 | 20-30 | 1.163 | 2-3/8 2-7/8 3-1/2 |

3/4 | |

| 25-150 RHAM | 38 | 1.642 | |||||

| 25(30)-175 RHAM | 44 | 2.235 | |||||

| API SPEC 11AX | 25-150RHAC/M | 38 | 0.6-8.0 | 0.6 | 1.642 | 2-7/8 | 3/4 |

| 25-175RHAC/M | 44 | 0.9 1.2 1.5 |

2.235 | 2-7/8 | |||

| 30-225RHAC/M | 57 | 3.694 | 3-1/2 | ||||

| 25-150RHBC/M | 38 | 1.642 | 2-7/8 | ||||

| 25-175RHBC/M | 44 | 2.235 | 2-7/8 | ||||

| 30-225RHBC/M | 57 | 3.694 | 3-1/2 |